The coke oven is a crucial piece of equipment in the metallurgical and chemical industries, playing a vital role in the production of coke, a key raw material for iron - making. Among its various components, the oven door may seem like a simple part, but it actually has multiple important functions. As a leading Coke Oven supplier, I'd like to delve into the role of the oven door in a coke oven.

1. Sealing Function

One of the primary roles of the oven door in a coke oven is to provide an air - tight seal. During the coking process, the coal inside the oven is heated to high temperatures in the absence of air to produce coke. Any leakage of air into the oven can disrupt the coking process. Oxygen in the air can react with the hot coke and coal, causing combustion and reducing the quality of the coke. Moreover, it can lead to an uneven heating profile within the oven, resulting in inconsistent coke properties.

A well - sealed oven door also prevents the escape of volatile compounds generated during coking. These volatile substances include coal gas, tar, and various hydrocarbons. If they leak out, they not only represent a loss of valuable resources but also pose environmental and safety hazards. Coal gas, for example, is highly flammable and explosive, and its leakage can lead to dangerous situations. Additionally, the release of tar and other pollutants can cause air pollution and contaminate the surrounding environment.

2. Heat Retention

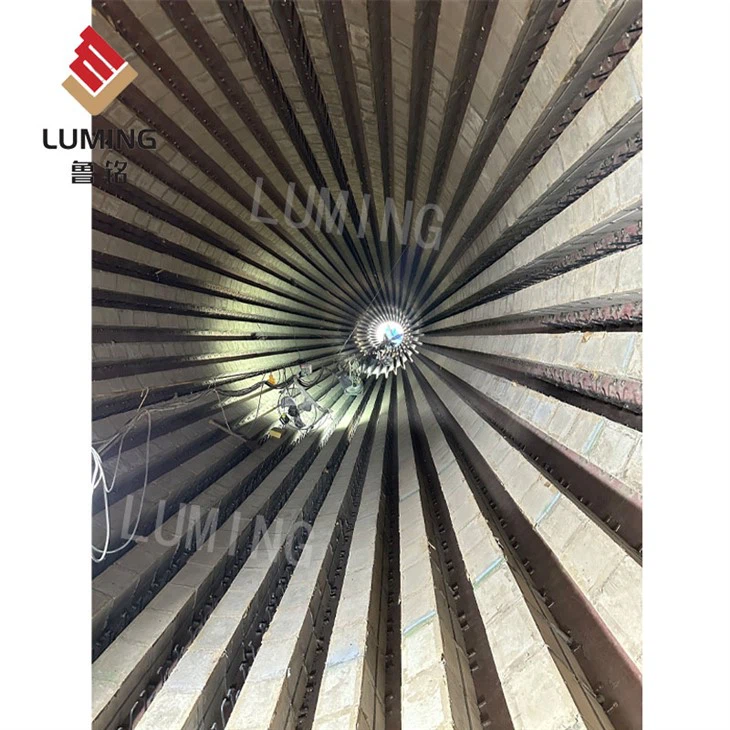

The coking process requires maintaining a high and stable temperature inside the oven. The oven door acts as a thermal barrier, helping to retain the heat within the oven. High - quality oven doors are usually made of materials with low thermal conductivity, such as refractory bricks and special insulation materials. These materials can effectively reduce the heat transfer from the inside of the oven to the outside.

By retaining heat, the oven door helps to ensure that the coking process proceeds smoothly. A stable temperature is essential for the proper decomposition and carbonization of coal. If the heat escapes too quickly, the temperature inside the oven may drop, leading to incomplete coking and lower - quality coke. Moreover, heat retention also contributes to energy efficiency. Less heat loss means less energy is required to maintain the desired temperature, which can significantly reduce the operating costs of the coke oven.

3. Safety and Maintenance

The oven door also plays an important role in ensuring the safety of the coke oven operation. It acts as a physical barrier, preventing operators from accidentally coming into contact with the high - temperature interior of the oven. In case of any abnormal situations inside the oven, such as an explosion or a sudden release of pressure, the oven door can help to contain the impact and protect the surrounding personnel and equipment.

In addition, the design of the oven door facilitates maintenance work. It can be easily opened and closed, allowing operators to access the inside of the oven for inspection, repair, and cleaning. For example, after a batch of coking is completed, the oven door can be opened to remove the coke and clean the interior of the oven. Regular maintenance helps to ensure the long - term and stable operation of the coke oven.

4. Impact on Coke Quality

The performance of the oven door can directly affect the quality of the coke produced. As mentioned earlier, a good seal and heat retention are crucial for a consistent coking process. A well - functioning oven door helps to maintain a uniform temperature and atmosphere inside the oven, which is essential for the formation of high - quality coke.

High - quality coke has a high carbon content, low ash and sulfur content, and good mechanical strength. These properties are determined by the coking conditions, and the oven door is an important factor in creating and maintaining these conditions. For example, a sealed oven door can prevent the ingress of oxygen, which helps to reduce the oxidation of coke and maintain its high carbon content.

Related Products

In addition to coke ovens, our company also offers a variety of other kilns and furnaces. For those interested in alumina processing, we provide Alumina Calcination Kiln. These kilns are designed to meet the specific requirements of alumina calcination, ensuring high - quality alumina production.

In the lithium industry, our Lithium Industry Kilns are widely used for the processing of lithium - containing materials. They are equipped with advanced technologies to ensure efficient and precise lithium processing.

We also have Hazardous Waste Incineration Kiln for the safe and effective disposal of hazardous waste. These kilns are designed to meet strict environmental standards and ensure the complete destruction of hazardous substances.

Contact for Purchase and Negotiation

If you are in the market for a coke oven or any of our other products, we invite you to contact us for further negotiation. Our team of experts is ready to provide you with detailed product information, customized solutions, and competitive pricing. Whether you are a small - scale enterprise or a large - scale industrial group, we can meet your specific needs.

References

- Smith, J. (2018). Coke Oven Technology and Operation. Metallurgical Publishing.

- Brown, A. (2020). Kiln and Furnace Design Principles. Chemical Engineering Press.

- Green, C. (2019). Environmental Considerations in Industrial Kiln Operations. Environmental Science Journal.